What are the technical limitations of sodium-ion batteries?

2024-02-28 17:26:27

Sodium-ion batteries are a battery technology with great potential, but they still face some difficulties in their production and mass production. First of all, raw material supply is the primary issue in sodium-ion battery production. Although sodium resources are relatively abundant, once the demand for sodium increases as rapidly as the demand for lithium, its price cannot be guaranteed to be stable.

At the same time, sodium mining and purification technology is relatively backward. After all, sodium has not received such great attention before. This has resulted in supply chain constraints that make it difficult to meet large-scale sodium-ion battery production needs. Secondly, the optimization of the sodium-ion battery production process is also a challenge.

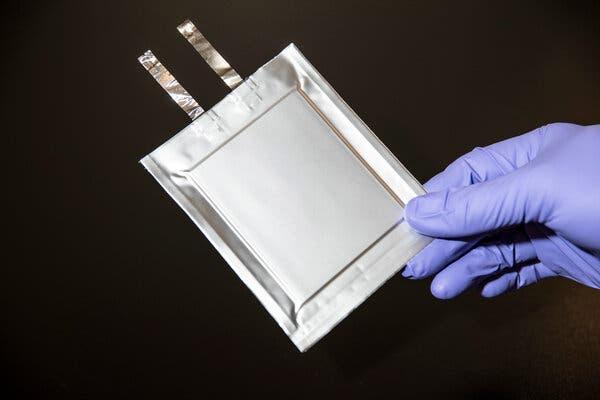

The production process of sodium-ion batteries requires highly precise control. The synthesis of materials, coating and assembly of electrodes and other links must not be sloppy. The problem is that instability often occurs in these links. These instabilities will affect battery performance and life and increase production costs.

Thirdly, safety is a key issue that needs to be paid attention to in the production of sodium-ion batteries. The sodium metal used in sodium-ion batteries is highly reactive when in contact with air and water, which can pose safety concerns. Therefore, strict safety measures need to be taken during the production process to ensure the safety during the production and use of sodium-ion batteries.

Finally, production cost is another issue that must be considered when mass-producing sodium-ion batteries. Compared with mature lithium-ion batteries, the production cost of sodium-ion batteries is higher. On the one hand, the cost of raw materials, on the other hand, the complexity of the production process and equipment investment will increase production costs.

The best way to reduce production costs is to achieve mass production. Once the volume is achieved, the cost curve can be flattened. This creates a paradox. Only when the cost is low and the market capital is large will bold mass production occur. If the cost is so high, mass production will be out of reach. The realization of improving production efficiency and reducing costs still faces many limitations.